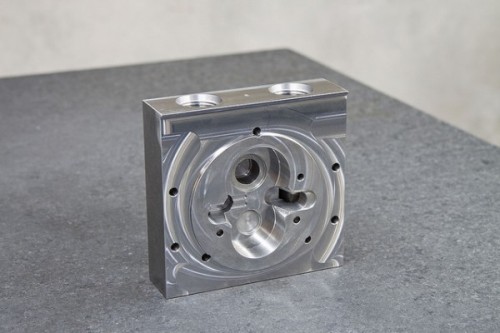

Our investment in cutting-edge CNC machining centers and CNC lathes ensures we can meet your project’s technical requirements and your expectations.

CNC Machining Centers

2023 Machining Center with pallet system and 21 tool magazine. BT 30 tool-holder system. 24000 RPM max. spindle speed. 2125 IPM rapid rate. .7 second tool change time. Table size 16.14″ x 33.46″. 1000 PSI High pressure coolant.

2005 Horizontal Machining Center with 7 pallet APC system (500mm pallets) 306 Tool MAM Matrix magazine 40 taper tool-holder system. 15,000 RPM Max. Spindle Speed 35 HP Coolant thru the spindle operating at 1000psi Renishaw Probe System – X 29.92″ x Y 29.92″ x Z 31.50″ Travel

2018 Horizontal Machining Center

40 Tool Fixed Pot ATC (BT 30) 15000 RPM Max.

spindle speed. 1000 PSI coolant thru the spindle.

Renishaw Probe. Rapid feed rate 2362 IPM. 12″ x 12″ x 13″

1996 Prototyping Mill with two axis CNC. 3 axis digital readout. Table size 10” x 50”. Travel 31” x 17” x 23.5”.

1998 Machining Center with pallet system and 14 tool magazine. BT 30 tool-holder system. 8000 RPM max. spindle speed. 1890 IPM rapid rate. 1.0 second tool

change time. Table size 15” x 25.6”.

2005 & 2011 Horizontal Machining Centers & 30 pallet (450mm 1997 Twin turret / twin spindle. 1300 IPM rapid traverse rate. pallets) RGV w/2 work stations. 200 tool chain magazine & 280 2” diameter bar capacity. 8” chuck. 12 tool position turret. Tool Matrix w/40 taper tool holder system. NC 4th axis table. 14,000 RPM Maximum 1968 IPM rapid rate. 30 HP. Through the spindle coolant. X 23.6″ x Y 23.6″ x Z 23.6″ Travel

CNC Turning Centers

2023 CNC Turning center with live tooling. 2-1/2″ Ø Bar capacity. 8 ” Chuck.4500 RPM with automatic bar feed. Rotating tool RPM 6000. 15/20 HP

1997 1” diameter bar capacity. 4” chuck. Gang tooling & air bar feeder.

2014 CNC Lathe featuring 2 spindles and 2 turrets, the main turret with Y axis function. 5000 RPM W/1-5/8″ Ø Bar Capacity Automatic Bar Feeder and High Pressure Coolant.

√

2011 CNC Lathe with 2-1/2” diameter bar capacity. 10” chuck, and collet system. 3500 maximum RPM. 1180 IPM rapid traverse rate. LNS hydraulic bar feed with up to 2 1/2” diameter bar capacity. Programmable hydraulic center.

2015 Twin turret / twin spindle. 1300 IPM rapid traverse rate. 4750 RPM. 8” chuck’s. 12 tool position turrets W/ Gantry Robot and High Pressure Coolant.

2006 Swiss Style Turning Center with seven axis. 1-1/4″ diameter bar capacity. Automatic bar feeder. High pressure coolant. 17 tool capability (four live). 8000 RPM maximum spindle speed.

Additional Equipment

Inspection Equipment

- Brown & Sharp CMM

- 2 Helmel Check Master CMM’s

- Optical Comparator

- Eddy Current Machine

- Profilometer

- Rockwell Tester

- Granite Surface Plates

- Height Gages & Certified Pin and Thread Gages

Sunnen Hone 1804

Index Vertical Milling Machine

Howa 1000 Engine Lathe

Clausing Engine Lathe

Burr King VibraKing 40